Products

Steel plate Pretreatment line – Longfa

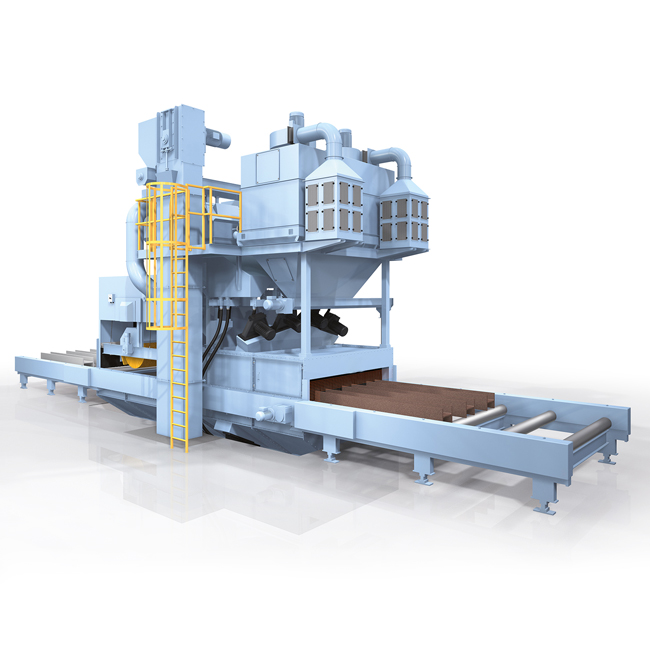

Steel Plate Pretreatment Line - Longfa

The steel plate pretreatment line is mainly composed of feeding and discharging conveyors, shot blasting chamber, blast cleaning device, shot material circulation system, dust removal system, paint spraying system, drying room, paint mist treatment device and electric control system, and can be equipped with horizontal movement up and down Material device, rain and sewage cleaning device, code scanning, coding device and steel plate preheating device. The steel pretreatment line process refers to the processing technology in which the surface of the steel is shot blasted to remove rust and coated with a layer of protective primer before processing (that is, the state of the raw material). After the steel is pretreated, the corrosion ability of mechanical products and metal components can be improved. The anti-fatigue performance of the steel plate prolongs its service life; at the same time, it can also optimize the manufacturing state of the steel surface, which is beneficial to the blanking and precision blanking of the CNC cutting machine. In addition, the steel plate pretreatment line can greatly improve the efficiency of steel plate surface cleaning, reduce labor intensity and environmental pollution.

Advantage

Continuous shot blasting wheel, stable conveying system, high safety.

Features

Overall solution.

All components use good suppliers.

Proven Capabilities, Superior Components, Mature Technology.

Tailor-made - flexible layout.

Easy integration into existing manufacturing processes.

Rich equipment selection.

Application

Remove oxide, rust, grease impurities, etc.

Increases surface roughness, fatigue strength and paint adhesion.